Guide to Scaffolding Types in Construction

Introduction

Scaffolding allows for safe access to heights for construction, maintenance, and repair operations. It guarantees stability and adherence to safety regulations while supporting personnel, equipment, and supplies.

Understanding the different kinds of scaffolding allows builders to choose the best system for their unique project requirements, ranging from residential to high-rise buildings. This article will cover concepts, components, popular scaffolding types, and real-world scaffolding implementations.

What Is Scaffolding in Construction?

It is a temporary framework made of metal, wood, or fibreglass that provides raised platforms for building operations. Scaffolding work includes building, utilising, and dismantling these structures while adhering to stringent requirements for height, bracing, and load capacity. Proper execution ensures worker safety and project efficiency on construction sites for bricklaying, facade installation, and painting.

Standards (vertical posts), ledgers (horizontal braces), transoms (platform supports), base plates, couplers (right-angle, swivel, putlog), platforms, and guardrails are examples of essential scaffolding components. Scaffolding clamps of various types, including right-angle clamps for ledgers, swivel clamps for diagonals, and putlog clamps for wall ties, ensure secure connections that are important to stability.

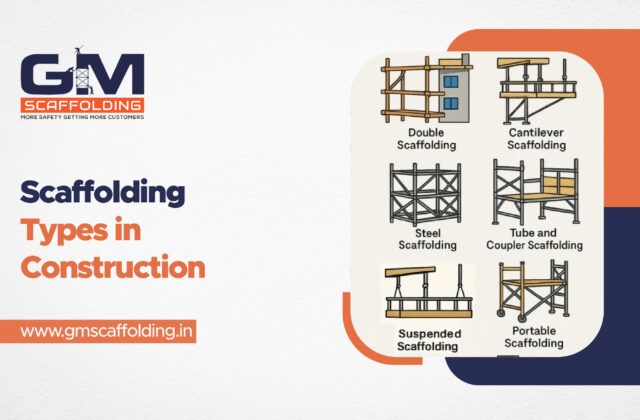

How Many Types of Scaffolding?

There are 8-12 major types that cover needs: single/double, cantilever, suspended, steel, trestle, mast climbers, mobile scaffolding, and system scaffolds. Scaffolding types differ by country, with bamboo in Asia, tube-and-clamp in the UK, and frame systems in the United States, each optimised for local materials, requirements, and tasks.

Scaffolding Types

Single Scaffolding

One row of standards parallel to the construction wall forms a single scaffold, often known as bricklayers’ scaffolding. For platform support, putlogs extend from the wall to ledgers. This works well with bare brick or block masonry when wall holes are used to secure putlogs. It is inexpensive for creating scaffolding at low to medium heights, but it needs sturdy wall ties.

Double Scaffolding

Double scaffolding is used for stone masonry or high loads, with two rows of standards. The inner row is near the wall, while the outer row provides additional stability through rakers and cross-bracing. It excels where drilling into walls is impractical, providing more rigidity for a variety of scaffolding requirements in large projects.

Cantilever Scaffolding

Cantilever scaffolding uses needles to thrust platforms outward through lower-level struts or wall holes. When full-height erection is limited by ground area, it works well for tall buildings, balconies, or upper-level repairs. Variants of needle scaffolding offer temporary overhang props.

Suspended Scaffolding

Suspended scaffolds with height-adjustable ropes or chains are suspended from overhead supports. They provide flexibility without interfering with the ground, making them perfect for high-rise building scaffolding. They are frequently used in facade cleaning, painting, and skyscraper maintenance.

Steel and Patented Scaffolding

Steel scaffolding creates strong, fire-resistant frameworks with tubes and couplers. It is more reusable than wood and can manage large loads in high-rise or industrial settings. Modular systems like Cuplock, Kwikstage, or Ringlock with quick-lock mechanisms for faster assembly in repetitive scaffolding work, are examples of patented scaffolding.

Understanding the differences between cuplock and ringlock scaffolding helps in selecting the right system for each project.

Mobile Scaffolding

Mobile scaffolding sections have wheels or casters for convenient transportation. Towers with movable legs and folding braces are ideal for inside jobs up to ten meters, such as painting or electrical work. Locking brakes provide stability on uneven surfaces. Proper set up of mobile scaffolding is essential to ensure safety and ease of movement during these tasks.

Applications Across Projects

- Single/Double: Masonry, plastering on walls.

- Cantilever/Suspended: Tall buildings, repairs.

- Steel/Patented: Industrial, commercial high-rises.

- Trestle: Low-height indoor jobs up to 5 meters.

Scaffolding rental in Coimbatore offers cost-effective steel or modular alternatives tailored to site requirements, reducing initial expenditures.

Related: https://blog.gmscaffolding.in/how-to-choose-right-scaffolding-rental-supplier/

Choosing the Right Scaffolding Types

Choose scaffolding types based on height, load (light, medium, or heavy-duty), site accessibility, duration, and weather. The ground conditions influence whether base plates or sole boards are used. Calculate safe working loads (SWL) of 200-600 kg/m² and install guardrails above 2 meters, toeboards, and tie-ins every 4 meters.

Match systems to tasks: patented for speed in apartments, single for bare walls, and double for heavy stonework. Always confirm that the names of scaffolding components, such as platforms and clamps, are compatible.

Related: https://blog.gmscaffolding.in/how-to-assemble-scaffolding-right-way/

Safety Essentials in Scaffolding Work

Safety is fundamental to all types of scaffolding used in construction. Competent professionals must design, install, examine scaffolds (daily/weekly), and label them green (safe), yellow (inspect), or red (do not use). Avoid collapses caused by wind, base settlement, inadequate assembly, or overload. Maintaining the right scaffold height for safety and efficiency is crucial to prevent accidents and ensure smooth workflow.

Mandates include:

- Complete planking without gaps.

- Double guardrails at open edges.

- Personal fall arrest systems above 2 meters.

- Weather shutdowns due to high winds.

- No unauthorised alterations.

Training covers harness use, load limits, and emergency procedures.

Innovations and Future Trends

Scaffolding styles advance with technology: lightweight aluminium eliminates human handling; motorised mast climbers accelerate high-rise access; and drone inspections lessen dangers. Software facilitates the creation of complex geometry, but eco-materials such as recycled steel enhance sustainability.

Conclusion

Mastering scaffolding types improves safety, speed, and cost in building. From single scaffolding for bare brickwork to patented scaffolding for efficiency, each is tailored to the specific scaffolding task at hand. Prioritise planning, quality components, and inspections while successfully utilising various forms of scaffolding.

FAQ

1.What is scaffolding in construction, and why is it important?

Scaffolding is a temporary platform that provides safe access and support at heights during building, repair, or maintenance.

2.What are the different types of scaffolding used in construction?

Common types include single, double, cantilever, suspended, trestle, steel, and mobile (tower) scaffolding.

3.What are the main components of scaffolding and their functions?

Standards, ledgers, transoms, base plates, planks, braces, and guardrails work together to support loads and ensure stability and safety.

4.What is the difference between single scaffolding and double scaffolding?

Single scaffolding is attached to a wall and is primarily used for brickwork, whereas double scaffolding has two rows for added support and is commonly used for stone masonry.

5.How do I choose the right type of scaffolding for a construction project?

Match the scaffolding to the height, load requirements, site conditions, duration, safety requirements, and budget, and then ensure compliance with local standards.